A Biased View of Black Hawk Parts

Wiki Article

An Unbiased View of Black Hawk Parts

Table of ContentsSome Known Details About Black Hawk Parts The Basic Principles Of Black Hawk Parts The Ultimate Guide To Black Hawk PartsBlack Hawk Parts Can Be Fun For Everyone

KAMAN K-1200 K-Max synchropter In a side-by-side blades setup, two horizontal, counter-rotating blades are mounted side-by-side on a helicopter (or transverse rotorcraft). black hawk parts. The anti-torque result is offered by the opposing rotation of the 2 main blades. The side-by-side configuration is among the feasible trip arrangements of a tilt-rotor aircraft, when the blades are in the upright placement to supply upright lift.It is vital that components are created as well as completed in a correct style. As a helicopter extra parts supper in the U.S.A., Jones Steel Products is right here to develop as well as end up helicopter parts in an exact and prompt manner. Jones Metal Products has over 95 years in the hydroforming sector, a procedure that we use for a variety of components in the aerospace and also protection markets.

As a helicopter components provider, Jones Steel Products regularly invites outdoors companies in for proper accreditations. These outside companies observe and also verify the different processes that we have on offer where we are making continuous advances in composite manufacturing of helicopter components. ISO 9001:2015 without Layout This certification ties to our quality administration system.

When it comes to being a trusted and valued helicopter components producer, making advances in composite manufacturing of helicopter components features the area. The procedures through which we manufacture helicopter parts are constantly being surpassed by our competent team. Our team of designers, developers, and also metalworkers have actually been innovating our services considering that the 1920s.

The Definitive Guide to Black Hawk Parts

They can even assist you to recreate older helicopter components that stem from stopped runs all while keeping in line with our high requirements of quality as well as constant manufacturing. Hydroforming, Rubber pad developing, Heat dealing with, Stretch forming As a top helicopter components maker, Jones Metal Products enjoys to collaborate with consumers in the aerospace, defense, as well as aircraft industries.

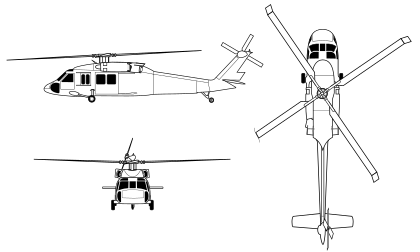

Helicopters are classified as rotary wing aircraft, as well as their rotating wing is commonly described as the primary rotor or just the blades. Unlike the much more typical fixed wing airplane such as a sport biplane or an airliner, the helicopter is qualified of direct upright liftoff and landing; it can also hover in a set placement.

The autogiro he consequently developed incorporated functions of both the helicopter as well as the airplane, although it resembled the last even more. The autogiro had a rotor that operated something like a windmill. When established in movement by taxiing cab on the ground, the rotor might produce extra lift; nevertheless, the autogiro was powered primarily by a traditional plane engine.

Some Ideas on Black Hawk Parts You Should Know

To guide a helicopter, the pilot has to adjust the pitch of the his explanation blades, which can be set three means. In the cumulative system, the pitch of all the blades connected to the rotor equals; in the cyclic system, the pitch of each blade is developed to vary as the blades rotates, as well as the 3rd system makes use of a combination of the very first 2.A related problem occurs because, as the helicopter relocates ahead, the lift under the blades that go into the airstream first is high, yet that under the blades on the opposite side of the blades is low. The web impact of these troubles is to undercut the helicopter. Generally, the means of making up for these important site uncertain variants in lift and drag is to make flexible blades linked to the blades by a hinge.

Torque, an additional trouble linked with the physics of a turning wing, triggers the helicopter fuselage (cabin) to turn in the contrary instructions from the blades, especially when the helicopter is relocating at reduced speeds or hovering. To counter this response, lots of helicopters utilize a tail rotor, an exposed blade or ducted follower installed on the end of the tail boom generally seen on these craft.

He experimented for even more than twenty years and also lastly, in 1939, flew his first trip in a craft referred to as the VS 300. Connected to the ground with lengthy ropes, his craft flew no greater than 50 feet off the ground on its very first several trips. Even then, there were troubles: the craft flew up, down, and sideways, yet not onward.

Black Hawk Parts for Dummies

as well as asked to try among their brand-new primary structure workplace computer systems. By 1951, Parsons was explore having the computer's estimations actually direct the machine tool. His ideas were eventually developed right into the computer-numerical-control (CNC) device tool market that has reinvented modern production methods. 1 Each individual tubular component is reduced by a tube reducing equipment that can be swiftly readied to generate different, exact lengths and specified batch amounts.For aside from small bends, tubes are loaded with liquified salt silicate that hardens and gets rid of kinking by creating the tube to flex as a solid bar. The Get More Info so-called water glass is then gotten rid of by putting thebent tube in boiling water, which melts the internal product. Tubing that has to be bent to match body contours is fitted over a stretch creating maker, which stretches the metal to a specifically contoured form.

The last process involves infusing wax or an alloy with a reduced melting factor right into a mold or die. When the theme has been created, it is dipped in liquified metal as sometimes as essential to accomplish the thickness preferred. When the component has dried out, it is heated up so that the wax or alloy will certainly thaw and also can be put out - black hawk parts.

Report this wiki page